Choosing the right material to make boats remains a headache among boat manufacturers. The best choice should be the one that can withstand external elements, keeping the passengers safe.

Why is HDPE a good material for boats? What do manufacturers use it for?

Today, we will answer these questions to give you a comprehensive explanation of HDPE. Let’s read on to discover!

Why Is HDPE A Good Material For Boats?

HDPE is durable, sturdy, flexible, safe, and high in resistance. All of these features make it an ideal solution for boat production.

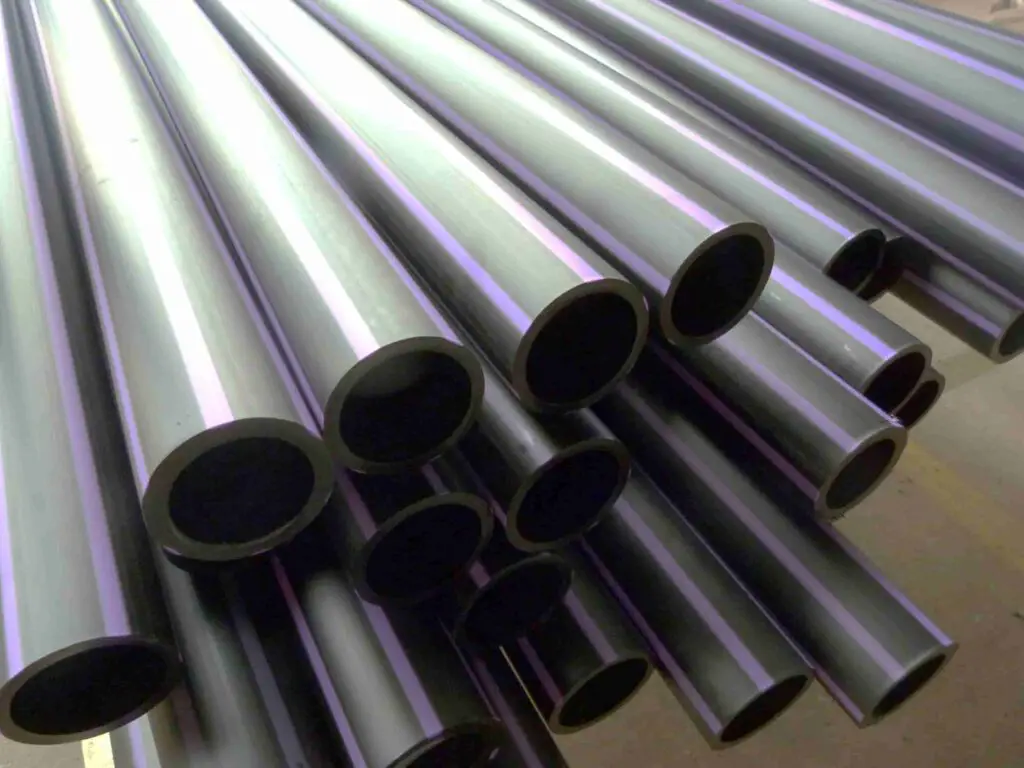

HDPE stands for High-Density Polyethylene. It’s a thermoplastic polymer made from the ethylene monomer. When applied in HDPE pipes, it has short names, like “polythene” or “alkathene.”

HDPE has a high strength-to-density ratio. People use it to make plastic lumber, geomembranes, corrosion-resistant pipework, and bottles.

When it comes to outdoor storage, docks, boats, and other equipment that must withstand the elements, HDPE is ideal because of many reasons.

Strength

The endurance of HDPE in relation to its thickness is one of its most impressive qualities. When choosing material for marine constructions, having robust building materials is essential because the environment can destroy standard materials like plywood.

Other wood-based materials have very little chance of achieving HDPE’s durability. Because of its strong impact and tensile toughness, you may rely on it to support you without fracturing.

Safety

In particular, HDPE is among the safest materials for constructing a boat.

Even with the right procedures, marine-grade wood may eventually rot and degrade. It leads to instances where brittle, deteriorating wood cracks.

For instance, walking on a fragile piece of wood on a pier can cause an injury immediately or perhaps a future security problem.

Moreover, making a hull out of HDPE might give it extra defense against many types of marine debris.

Resistance

HDPE shows remarkable resistance to a variety of chemicals available outside.

It is resistant, so extended exposure to the sun won’t cause its color to fade. Hence, HDPE has replaced wood in many different marine uses.

Indestructible HPDE is resistant to scratches and bumps. Rocks or sharp objects won’t puncture it as a result.

Flexibility

The malleability of this polymeric substance brings out another benefit.

HDPE has a high melting point, which keeps it rigid even at extremely high temperatures.

However, you can quickly and efficiently mold it into any form when it reaches that melting point.

As a result, HDPE can serve many projects that prioritize flexibility, such as cutting boards, piping, plastic lumbers, etc.

Weight

HDPE is a versatile material. It has a density of 930 to 970 kg/m3, making it lighter than water. HDPE is hence very buoyant, even when underwater

Zero corrosion

Materials degrade over time as a result of contacting external conditions. Hence, manufacturers always try to seek substances with the most corrosion resistance.

Due to its resistance to decay, mildew, and mold, HDPE is one of the best materials for boat production.

Furthermore, HDPE has exceptional resistance to naturally present substances in soil and can tolerate most strong mineral bases and acids.

In addition, the material is almost impenetrable to water, acids, solvents, soaps, and cleaning agents.

Environmental impact

Given how much plastic people waste daily, plastic recycling should be one of the primary factors when choosing a material.

HDPE plastic, luckily, is easily recyclable, preventing non-biodegradable trash from ending up in landfills and reducing up to 50% of plastic production.

As a result, HDPE can be the right material for you if you’re searching for a reasonably priced, environmentally friendly substance.

Boating Applications for HDPE

A boat can use HDPE for many components since it is more durable, safe, and low-maintenance than wood-based solutions.

Installing HDPE around your existing dock gradually will allow you to explore and learn about its capabilities first.

Here are some examples of boat components for switching from wood to HDPE:

Handles and Hatches

A broken hatch or handle could, at most, cause a minor accessibility issue.

But instead of using wood to fix the problem, you can install a new HDPE handle to see how it can work.

Railings

Railings are essential for guaranteeing passenger safety.

These decayed constructions’ wooden pieces will cause cuts, or a sudden break could result in casualties from debris falling.

You need a sturdy material for railings, and HDPE will be a fantastic solution. If your wooden railings have broken down, consider using HDPE instead.

Cabinets and Furniture

HDPE is more resistant to stains and damage than wood.

It can also do a better job of handling odors, rot, chips, and scratches. Hence, you won’t go wrong with furniture and cabinets made of HDPE.

Motor Covers

The weather usually causes this place to deteriorate severely.

Maintaining the cover in good condition is essential for the longevity of your boat’s engine because it acts as the engine’s shield.

You will want to use HDPE for this part because of its durability. Molding the material into the desired shape is also an easy task.

Frequently Asked Questions

1. Is HDPE a plastic?

Yes. HDPE is petroleum thermoplastic and the most commonly used kind of polyethylene for various applications.

2. Is HDPE cheaper than metal?

Metal is a popular material for structures because of its inexpensive initial cost.

However, you won’t find metal a cost-effective investment in the long term because of the high requirement for maintenance, cleaning, and painting.

Metal is initially less expensive than HDPE plastic, but HDPE plastic costs less over time. HDPE can make products that are maintenance-free and long-lasting.

3. Is HDPE stronger than steel?

Steel is stronger than HDPE. Working with HDPE has one benefit: it is a little softer, which makes it less prone to damage pieces during a washing process.

4. Can HDPE be glued?

Yes. There are two ways to glue HDPE:

- Weld the plastic pieces together

- Use epoxy-based HDPE glue or the right superglue with a primer

You can glue HDPE easily with the correct adhesive. Remember to read the instructions carefully before bonding the pieces together.

Read More: Blazer Bay 2400 Problems: All That You Need To Know

Conclusion

HDPE is popular in boat-making because of its durability, resistance, zero corrosion, flexibility, and recyclability. HDPE appears to be an excellent alternative to wood, thanks to those traits.

Hopefully, we have satisfactorily answered your question. If you need any further information, please comment in the section below. We will get back to you soon.

Thank you for reading!

I’m Cindy, a free-spirited outdoor enthusiast. Since childhood, Our family frequently goes on weekend camps and my father, who was a skilled hunter, used to teach my siblings and me valuable things about wildlife survival. I made this blog to share my knowledge, experiences, and tips.

![Bass Hunter vs Pelican: [Which One Is Better Boat?]](https://huntandlunch.com/wp-content/uploads/2022/11/Bass-Hunter-Vs-Pelican-768x768.jpg)